It is the direct participation of production operators in the management of the machines through daily checks, lubrication, early detection of abnormalities, replacement of parts or small repairs

1. Purpose of AM

- The purpose of an Autonomous management program is threefold.

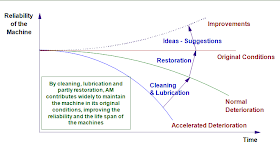

First, it brings production and maintenance people together to reach a common goal: to stabilize equipment conditions and stop accelerated deterioration. Operators learn to execute important daily tasks like cleaning, inspection, lubrication, quality checks and other light maintenance tasks like simple replacements and repairs.

- Second, the program is designed to train operators about how their equipment works, what common problems can occur and how these problems can be prevented by early detection and treatment of abnormal conditions.

Third, the program prepares operators to be active partners with maintenance and engineering personnel in improving the overall performance and reliability of equipment.

- In average 70% of the failures and of the downtime in the process and assembly industry, are caused by lack of proper cleaning, inspection, lubrication and tightening (CILT).

Traditionally the general attitude on the shop floor has been

“ I run it, you fix it”

Operators can easily prevent many breakdown, short stop, waste and quality problems by learning how to recognize abnormal conditions and how to link these abnormal conditions with losses.

By now it should be clear that this way of thinking does not promote optimal performance.

AM teaches production operators to understand their equipment. Equipment knowledge is no longer limited to how to produce, now it also include the following valuable skills:

The ability to ESTABLISH equipment conditions,

knowing how to distinguish between normal and abnormal conditions

The ability to MAINTAIN equipment conditions,

knowing how to ensure that normal equipment conditions are met

The ability to RESTORE equipment conditions,

knowing how to respond quickly to abnormalities

When operators have acquired these three skills, they will be understand the equipment well enough to recognize the causes of future problems. They will realize when the machine is about to produce defects or break down. They will also be able to respond quickly.